The characteristic of the machine:

Introduce

SMD-90 SHUNDA Machinery has successfully developed its own medium-speed automatic paper cup forming machine with complete intellectual property right to meet the increasing demands for paper cups (bowls) in the market. This equipment is an automatic multi-position machine that can finish the whole process of paper cup (bowl) making from automatic paper conveying, connecting, bottom making, heating, boarder knurling, oiling, rimming and collective packaging etc. With compact structure and strict action control, the machine specialized in production of paper cups (bowls) or conical food containers is precise, easy to operate, Intelligent, safe, stable and dependable.

Specifications:

|

MODEL

|

SMD-90

|

|

SPEED

|

100-120 PCS/MIN

|

| MAX SPEED |

150 PCS/MIN |

|

CUP SIZE

|

> 16OZ

|

| SIZE RANGE |

TOP DIAMETER:90

BOTTOM DIAMETER:80

HEIGHT:140

|

|

MATERIAL

|

135-450GRAM

|

| RUNNING POWER |

11KW |

|

CONFIGURATION

|

ULTRASONIC

|

| CONFIGURATION |

HOT AIR SYSTEM |

|

OUTPUT

|

380V/220V,60HZ

|

|

AIR COMPRESSOR

|

0.5 M³/Min

|

|

NET WEIGHT

|

3500 KGS

|

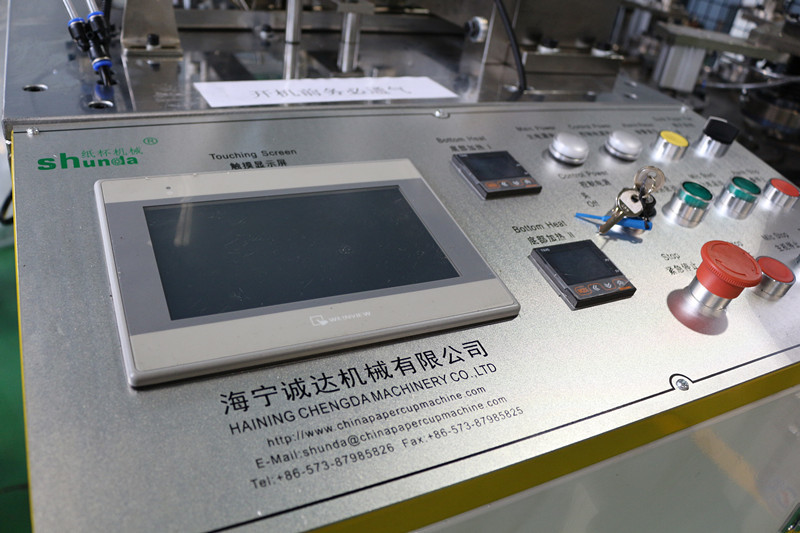

Machine picture

Paper cup machine forming theory

Advantages

1.High speed paper cup forming machine comes with two turnplate, open cylinderical cam mechanism and gear transmission, longitudinal axis structures.

2. The whole machine adopts automatic lubrication system, which makes all mechanical parts working much more smoothly.

3. Bottom sealing by hot air devices, so that the machine is efficient.

4.The new machine with higher working speed with extra hot air system for the side sealing, so side sealing is done by both Hot air and Ultrasonic.

5. Cup side sealing by ultrasonic, Evergreen which is made in Taiwan.

6. Cup top curling has two steps, rotary curling and heating figuration, which makes the curling more stable and with better appearance (round and smooth).

7. The machine comes with PLC control system, sensor failure detecting and it stops working automatically if the machine has any problem, it can greatly improve operation safety and reducing labor cost. THE PLC, touch screen, Invertor, temperature controller and sensor is made in Korea.

8. More efficient and higher performance.

9. With automatic cup delivery system and counter.

FAQ

1. Q: Are you trading company or factory?

A: We are factory.Both machine make by ourself

2. Q:Where is your factory located?

A:Our factory is located in Haining city, Zhejiang province. Next to Shanghai and Hangzhou city.

3. Q:How does your factory do regarding quality control?

A:Quality is priority. Shunda people always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

4. Q: How you guarantee the quality?

A: 3 year warranty for mechinical parts and 1 years for electricity parts

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!