Introduce

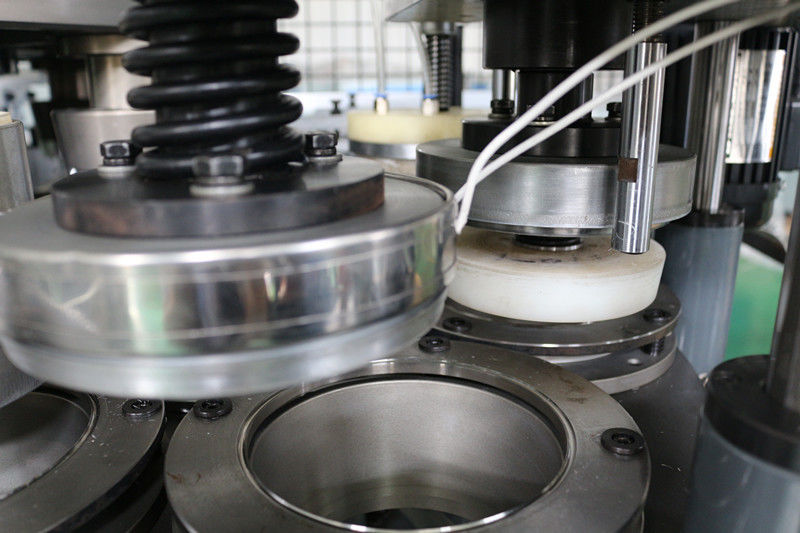

SMD-90 SHUNDA Machinery has successfully developed its own medium-speed automatic paper cup forming machine with complete intellectual property right to meet the increasing demands for paper cups (bowls) in the market.

Specifications:

|

MODEL

|

SMD-90A

|

|

SPEED

|

100 PCS/MIN

|

|

CUP SIZE

|

> 16OZ

|

|

MATERIAL

|

135-450GRAM

|

|

CONFIGURATION

|

ULTRASONIC&HOT AIR

|

|

OUTPUT

|

380V/220V,60HZ

|

|

AIR COMPRESSOR

|

0.5 M³/Min

|

|

NET WEIGHT

|

4 .5 TONS

|

Installation

When you install the machine,should pay attention for keeping the machinery in level.Install Address Should note The equipment Operation,Maintain,and fix’s necessary space.

Technological Process

Advantages

- Quality assurance both for our products and service for after-sales.

- Favorable price.

- Great variety of products.

- Attractive design.

- Environment Friendly Technology

Our QC team

A QC team with more than 10 professional and technical personnel. To ensure 100% products checking.

Material: Strictly control of material using, meet international requested standards.

Semi-finished products inspection: Product inspection before 100% finished.

Production line test: With work team or data engineer who will inspect machines and lines at fixed period.

Finished Product Inspection: Quality and property test before products are packed and loaded.

FAQ

1. about machine

Q: What is a paper cup machine, and what are its core working steps?

A: A paper cup machine is automated equipment for producing disposable paper cups. It processes PE - coated paper blanks and bottom paper rolls into finished cups through these key steps: paper feeding → sealing (heat / ultrasonic) → bottom forming → curling → quality inspection → packaging

2. about raw material

Q: What raw materials are needed for a paper cup machine? What GSM is suitable?

A: Required materials: single / double PE - coated pre - cut and printed fan - shaped paper, bottom paper rolls, food - grade silicone oil, and a small air compressor. The typical GSM range is 150–180 for small cups and 180–310 for large / double - wall cups, balancing sturdiness and cost.

Q: Can one machine make multiple cup sizes? How to change molds?

A: One machine comes with one standard mold set. To make different sizes, you can buy extra half - set molds (easy to replace) or full - set molds (difficult, low success rate). It is recommended to change 1-2 half-set ofmolds with the same bottom diameter. Frequent mold changes will prolong downtime and damage parts, especially for high - speed machines.

Q: What else do I need to start production? How to install and get training?

A: Besides the machine and raw materials, prepare food - grade silicone oil and a small air compressor. Machines are pre - installed and tested before delivery. Suppliers usually provide operation / training videos; on - site training can be arranged for an extra fee.

Q: How to maintain the machine? What about warranty and repairs?A: Maintenance tips: daily cleaning of molds and feeding paths; weekly inspection of screws, belts, and electrical connections; monthly lubrication of moving parts. Most suppliers offer 12–24 - month warranties. For faults, suppliers provide video guidance; faulty parts under warranty are replaced free of charge.

Q: What key factors should I consider when buying a paper cup machine?A: Focus on: 1) Production capacity (match your output: 50–120 cups / min for small machines, 100–200 cups / min for industrial models); 2) Ease of operation and mold change; 3) Energy consumption and maintenance costs; 4) After - sales support, warranty, and spare part availability; 5) Space fit (measure your workshop beforehand).

Q: What safety measures should I take when operating the machine?A: Operators must wear gloves and goggles; ensure all parts are fastened; follow safety protocols; keep the workspace unobstructed; perform regular safety checks and fix issues promptly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!