Double Turnplate Paper Tea Cup Making Machine 0.4m³ / Min 0.5MPA

Description:

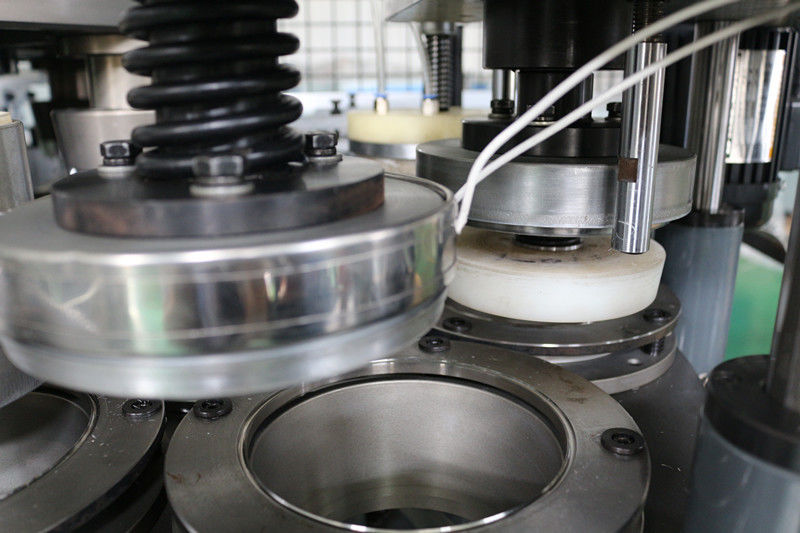

MODEL SMD-90 double turnplate high speed paper cup machine is fit for making hot

and cold drinks cup.This model can fit for making 2oz to 16oz cup sizes, new driving

system and with cup detection system as option by customers.

* Switzerland Hot air sealing device

* Mitsubishi PLC tracking and Touch screen Controlling cabinet

* Servo-driven bottom-web feed with infinitely variable setting

* Automatic lubrication system

* Infinitely variable drive

Specification:

|

MODEL

|

SMD-90

|

|

SPEED

|

120-160 PCS/MIN

|

|

CUP SIZE

|

< 20OZ

|

|

MATERIAL

|

135-450GRAM

|

|

CONFIGURATION

|

ULTRASONIC&HOT AIR

|

|

OUTPUT

|

380V , 60HZ , 12KW

|

|

AIR COMPRESSOR

|

0.4 M³/Min

|

|

NET WEIGHT

|

3.4 TONS

|

|

MACHINE SIZE

|

2500 ×1800 ×1700 MM

|

|

COUNTER SIZE

|

900 ×900 ×1760 MM

|

Details:

Advantages:

1. One machine with one mould for free, the mould size according to buyer’s

2. Divided box: 125’ type, it has the long life than 100’

3. Valve:SMC(Japan)

4. Transducer: Danfoss(Danmar

5. Machine and eletricity cabinet are seperately, to avoide the dusty and Eleltricity parts ,damage by Vibration, or cable aging.

6. Use Stainless Steel plate, plastics sparying with the machinery surface.

7. Chinese brand Bearing and speed reducer

Whole Process:

Cup Sample :

After Service :

1 The CD and service&support guide booklet will be sent with machine to guide the installation process works,adjust the whole machine,production,avoid or solve the problem which the buyer will face.

2. Test run of the machine&training:

We will adjust the machine well for one week before the deliverying,ensure the machine has the perfect performace!

3. We can dispatch technologists to buyer’s factory,guiding installation,adjustment for a period,the buyer incharge of the salary, traffice fee,boarding and lodging, communication.

4.Training of buyer in China:

We supply the free training of buyer,the training won’t stop until the buyer control the whole lesson!The cost of air ticket,boarding and lodging should provided by buyer

5. We supply the consumable spare parts for free for two years use

FAQ:

1. about machine

Q: What is a paper cup machine, and what are its core working steps?

A: A paper cup machine is automated equipment for producing disposable paper cups. It processes PE - coated paper blanks and bottom paper rolls into finished cups through these key steps: paper feeding → sealing (heat / ultrasonic) → bottom forming → curling → quality inspection → packaging

2. about raw material

Q: What raw materials are needed for a paper cup machine? What GSM is suitable?

A: Required materials: single / double PE - coated pre - cut and printed fan - shaped paper, bottom paper rolls, food - grade silicone oil, and a small air compressor. The typical GSM range is 150–180 for small cups and 180–310 for large / double - wall cups, balancing sturdiness and cost.

Q: Can one machine make multiple cup sizes? How to change molds?

A: One machine comes with one standard mold set. To make different sizes, you can buy extra half - set molds (easy to replace) or full - set molds (difficult, low success rate). It is recommended to change 1-2 half-set ofmolds with the same bottom diameter. Frequent mold changes will prolong downtime and damage parts, especially for high - speed machines.

Q: What else do I need to start production? How to install and get training?

A: Besides the machine and raw materials, prepare food - grade silicone oil and a small air compressor. Machines are pre - installed and tested before delivery. Suppliers usually provide operation / training videos; on - site training can be arranged for an extra fee.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!