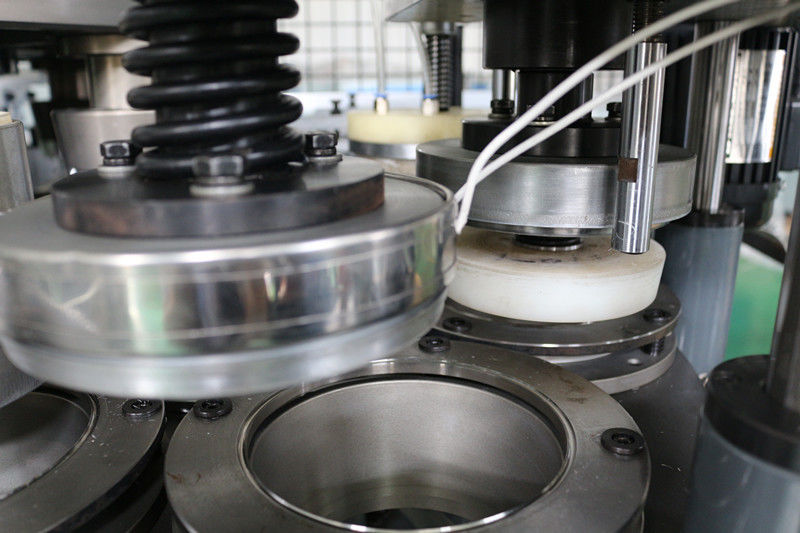

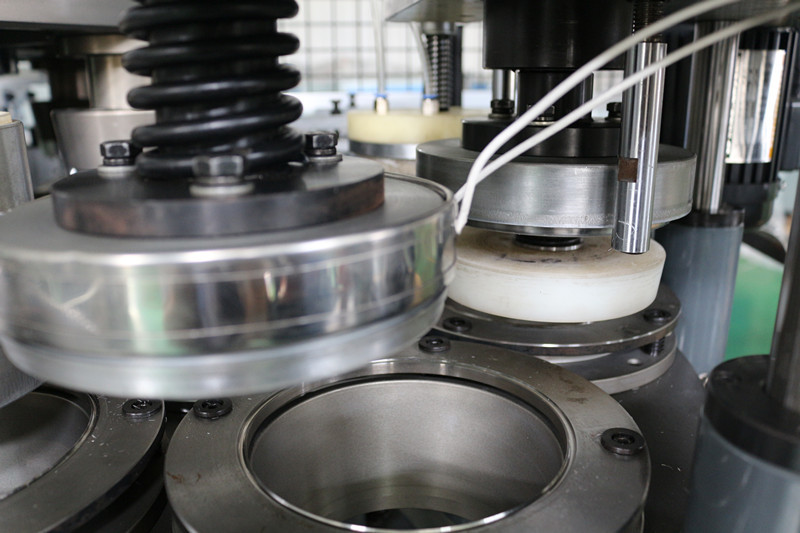

Fully Automatic Disposable Paper Cup Making Machine Ultrasonic Heating System

1. Machine introduction of Paper Cup Making Machine Price

SMD-90 could make single/double PE-coated paper cup. The machine is the automatic environmental machine with multi-running

positions. This machine runs a whole procedure of paper feedint,cup-fan-wallsealing.oiling.botom punchint,hearing,rolling,rimming,rounding and trip Ping. It ia an idol equipment of producing dringking cup,ice cream cup and other food cone-shaping containers.This type paper cup machine mainly used to making single /double PE coated cups from 3oz to 46oz.

2. Technical parameters of Paper Cup Making Machine

| Technical Parameters |

Value |

| Application |

Paper Cup Production |

| Dimension |

2500x1800x1700 Mm |

| Feature |

High Speed Forming |

| Power Supply |

220V/380V |

| Model |

SMD-90 |

| Material |

135-450 Gsm Paper |

| Collector Dimension |

900*900*1760mm |

| Cup Size |

2-46 Oz |

| Warranty |

2 Years |

| Automatic Grade |

Fully Automatic |

3 Maintaince Notice

1.Don't be in an environment of corrosive gas or smoke

2. Don't in the product may be splashed water, oil or use chemicals.

3. Please with stable voltage source power supply

4. make sure the power cord in good condition, so as not to cause fire or shock damage.

5. Instrument after electrify please don't touch input and output terminals, lest cause electric shock or instrument malfunction.

6. if you open the instrument shell, there may be a shock hazard.Because of power, has its internal capacitance charging, can keep certain voltage.

4 Working principles:

1. Square paper pieces be printed(use offset printer)and cut(use die-cutting machine)in

advance, becomes cup-fan-wall-papers to make cup body.

2. Paper sender delivers the cup-fan-wall-papers to molds, sealing the body.

3. The cup bottom paper (reel) automatic feed to the bottom cut parts, be cut into round

pieces and sent to molds with the sealed cup body.

4. Pre heating the cup bottom, bottom heating, curlinging the top edge.

5. Sealing the bottom with body.

6. Knurling the cup bottom.

7. Discharging finished cups automatically from molds. Sending to collector and be collected

and piled and counted automatically

5 Free Training Service

6 Customization

Paper Cup Forming Machine - Shunda

Customization Service

Brand Name: Shunda

Model Number: SMD-90

Place of Origin: Zhejiang China

Certification: CE

Packaging Details: Two sets per 20ft container

Delivery Time: 20-25 working days

Payment Terms: LC, TT

Supply Ability: 20 sets a month

Weight: 3400 Kg

Cup Size: 2-16 Oz

Color: White Or Customized

Collector Dimension: 900*900*1760mm

Capacity: 130 Cups/min

Key Words: Ice Cream Paper Cup Making Machine, Ice Cream Paper Cup Making Machine, Ice Cream Paper Cup Making Machine

7 Packing and Shipping

Packaging and Shipping for Paper Cup Forming Machine

Packaging:

The Paper Cup Forming Machine will be carefully packaged to ensure its safe delivery to customers.

8 FAQ:

-

Q: What is the brand of this product?

A: The brand name of this product is Shunda.

-

Q: What is the model number of this product?

A: The model number of this product is SMD-90.

-

Q: Where is this product manufactured?

A: This product is manufactured in Zhejiang, China.

-

Q: Is this product certified?

A: Yes, this product is certified with CE certification.

-

Q: How is this product packaged for shipping?

A: This product is packaged in sets of two per 20ft container.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!