Stable Fully Automatic Paper Cup Machine For Disposable Tea And Coffee Cups

1.Machine introduction of Paper Cup Machine

Type SMD-90 single or double PE coated paper cup machine is the automatic environmental machine with multi-running positions. This machine runs a whole procedure of paper feedint,cup-fan-wallsealing.oiling.botom-punchint,hearing,rolling,rimming,rounding and trip Ping. It ia an idol equipment of producing dringking cup,ice-cream cup and other food cone-shaping containers.This type paper cup machine mainly used to making one side or double side PE coated cups from 3oz to 46oz.Shaped special specifications to plans to OEM

2.Technical parameters of Paper Cup Machine

| Model |

SMD-90 |

|

|

|

| Capacity |

pcs/min |

100-120 |

90-110 |

80-100 |

| Size Range |

mm(max) |

Top diameter:90

Bottom Diameter:80

Height:140 |

Top diameter:110

Bottom Diameter:80

Height:170 |

Top diameter:125

Bottom Diameter:100

Height:170 |

| Suitable Paper Thickness |

gsm |

135-450 |

|

|

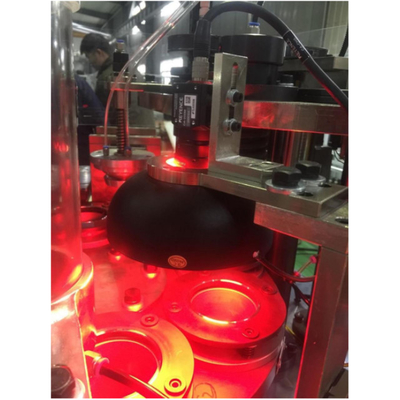

| Sealing Method |

|

Ultrasonic and hot air system |

|

|

| Running Power |

KW |

10 |

11 |

12 |

| Air compressor |

|

0.4m²/Min. 0.5MPa |

0.5m²/Min. 0.5MPa |

0.6m²/Min. 0.5MPa |

| Net weight |

Kgs |

3400 |

3500 |

3600 |

| Machine dimension |

mm |

2500*1800*1700 |

2600*1800*1800 |

2700*1800*1800 |

| Collector Dimension |

mm |

900*900*1760 |

1000*900*1860 |

1100*900*1860 |

Standard spare parts for SMD-90

Working principles:

1. Square paper pieces be printed(use offset printer)and cut(use die-cutting machine)in

advance, becomes cup-fan-wall-papers to make cup body.

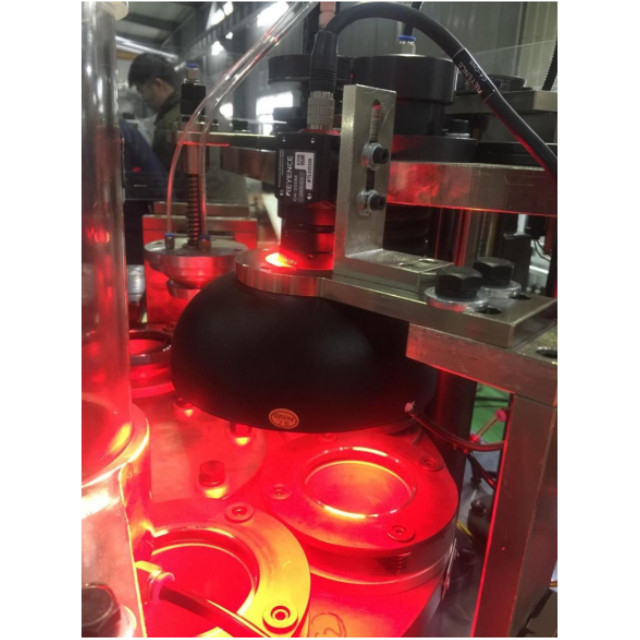

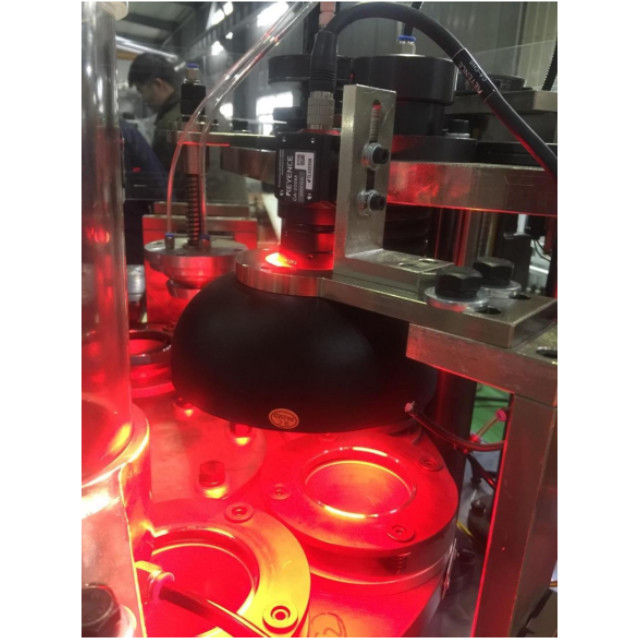

2. Paper sender delivers the cup-fan-wall-papers to molds, sealing the body.

3. The cup bottom paper (reel) automatic feed to the bottom cut parts, be cut into round

pieces and sent to molds with the sealed cup body.

4. Pre heating the cup bottom, bottom heating, curlinging the top edge.

5. Sealing the bottom with body.

6. Knurling the cup bottom.

7. Discharging finished cups automatically from molds. Sending to collector and be collected

and piled and counted automatically

Our after-sale

1.The CD and service&support guide booklet will be sent with machine to guide the installation process works,adjust the whole machine,production,avoid or solve the problem which the buyer will face.

2.Test run of the machine&training:

We will adjust the machine well for one week before the delivery, ensure the machine has the perfect performance!

We can dispatch technologists to buyer’s factory, guiding installation, adjustment for a period, the buyer incharge of the salary, traffic fee,boarding and lodging, communication.

3.Training of buyer in China:

We supply the free training of buyer,the training won’t stop until the buyer control the whole lesson! The cost of air ticket,boarding and lodging should provided by buyer

4.We supply the consumable spare parts for free for two years use

Contact

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!