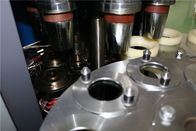

Disposable Tea Paper Cup Making Machine With Ultrasonic And Hot Air System

Introduction:

Shunda SMD-90 paper cup machine is a high gram paper cup shaping machine, it runs a whole procedure of the paper feeding, gluing, oiling, and bottom punching, heating, rolling, rounding, and tripping.It is an automatic machine you can control the speed according to the production.

For a better cup body and bottom connection, it used ultrasonic and hot air for heating, the heating phase into three steps, advanced technology allowed facility more safty both on itself and operator.It is an ideal equipment to make the paper cups for hot drink, cold drink, and ice cream paper cups.

It is intellectualization equipment, easy to operate (one person).It has the whole production line from paper fan to ready paper cup.

Picture:

Specification:

| Model |

SMD-90 |

|

|

|

| Capacity |

pcs/min |

100-120 |

90-110 |

80-100 |

| Size Range |

mm(max) |

Top diameter:90

Bottom Diameter:80

Height:140 |

Top diameter:110

Bottom Diameter:80

Height:170 |

Top diameter:125

Bottom Diameter:100

Height:170 |

| Suitable Paper Thickness |

gsm |

135-450 |

|

|

| Sealing Method |

|

Ultrasonic and hot air system |

|

|

| Running Power |

KW |

10 |

11 |

12 |

| Air compressor |

|

0.4m²/Min. 0.5MPa |

0.5m²/Min. 0.5MPa |

0.6m²/Min. 0.5MPa |

| Net weight |

Kgs |

3400 |

3500 |

3600 |

| Machine dimension |

mm |

2500*1800*1700 |

2600*1800*1800 |

2700*1800*1800 |

| Collector Dimension |

mm |

900*900*1760 |

1000*900*1860 |

1100*900*1860 |

After-sale and warranty:

We support 3 years warranty about machinery and free training.The service&support guide book and

CD will be sent with the machine to guide installation process adjustment and sove the problem maybe

the buyer will face.If you have any question any time just email us or call us directly.

How paper cup are made:

The production process of paper cups involves the use of specialized paper cup machines. Sheets of paper are fed into the machine, where they are precisely cut, formed, and sealed to create the cup shape. The machine ensures accurate alignment and smooth edges, while also applying any necessary coatings or finishes. After the forming process, the cups are inspected for quality and packaged for distribution. This automated process guarantees consistent, high-quality paper cups.

Usage in the world

Countries with a high demand for disposable products include those with significant coffee consumption, such as Brazil, Switzerland, Colombia, and Vietnam, where the popularity of coffee culture drives the demand for disposable paper cups. Additionally, countries where fast-food culture is prevalent, like the United States and China, tend to have a higher demand for disposable paper bowls, as they are commonly used in street food and casual dining settings.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!