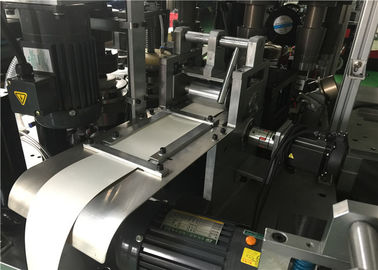

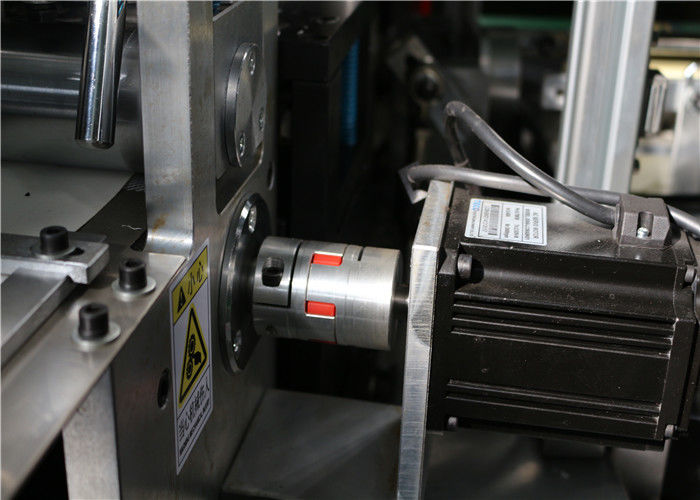

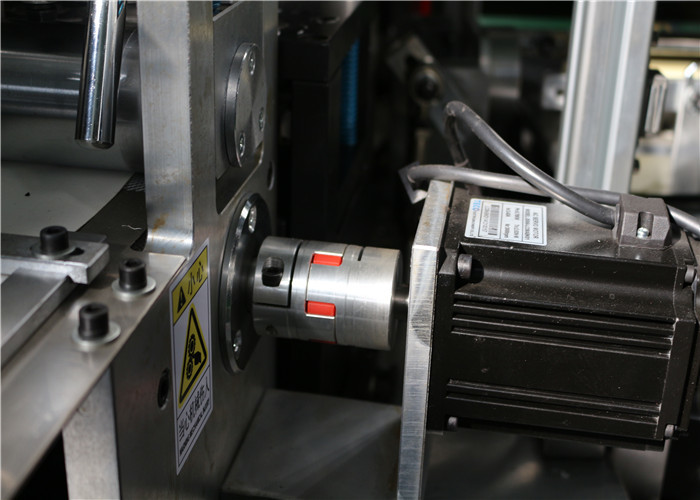

Intelligent Disposable Paper Tissue Container Potato Chip Container Paper Tube Machine

Specifications:

|

MODEL

|

STD-80

|

|

SPEED

|

70-80 PCS/MIN

|

|

CUP SIZE

|

Diameter 90mm max, height 220mm max

|

|

MATERIAL

|

135-450GRAM

|

|

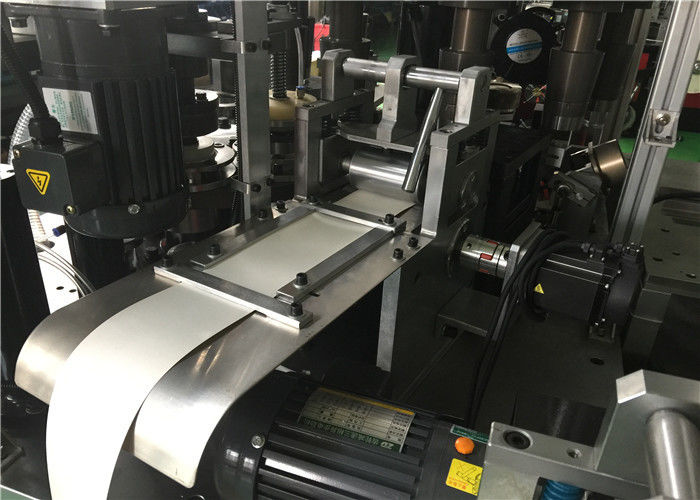

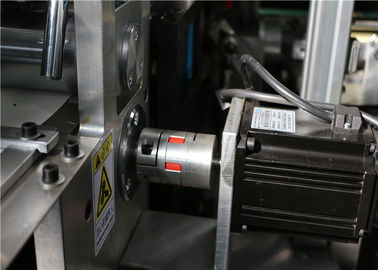

CONFIGURATION

|

Ultrasonic and hot air heating system

|

|

OUTPUT

|

380V/220V,60Hz/50Hz

|

Description:

STD-80 paper tube making machine is designed for making cylinder paper cans with bottom. It fits the most basic materials, such as PE,PLA,aluminum coated paper board. The paper can provides with moisture-proofe, light barrier and heat resistance functions. It suits all kinds of crisps food package for next packing generation.

Product advantage :

1. Environmental protection: The paper used in paper straight food packaging is biodegradable and recyclable, and is environmentally friendly.

2. Protect food: For food that is fragile or needs special protection, paper packaging can provide adequate support and protection, reducing the risk of breakage and contamination during transportation and storage.

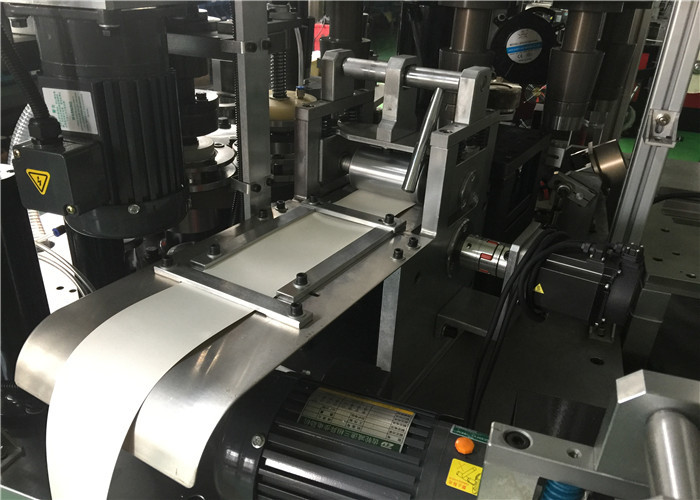

3. Beautiful and practical: paper straight packaging is convenient for printing and decoration in various colors. When Shunda Machinery makes straight packaging, it introduces an edge trimmer to process the edge of the sealed paper, which can better prevent grease leakage and provide better sealing.

4. Cost-effectiveness: Compared with traditional straight packaging, the price of Shunda Machinery paper packaging materials is relatively low, the processing steps are fewer than the traditional production process, and the cost is lower

Cup Size

Our QC team

A QC team with more than 10 professional and technical personnel. To ensure 100% products checking.

Material: Strictly control of material using, meet international requested standards.

Semi-finished products inspection: Product inspection before 100% finished.

Production line test: With work team or data engineer who will inspect machines and lines at fixed period.

Finished Product Inspection: Quality and property test before products are packed and loaded.

Whole Process

FAQ

1. Q: Is your company a factory or trading company?

A: Our company is a factory.

2. Q: Do you have Guiding Box or CD video for clients?

A: Yes,we have,we will send guiding box with CD together to clients.

3. Q: what about your payment?

A: We accept T/T,L/C payment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!