Production Speed 80 Disposable Paper Material Kebab Box Making Machine

Specification:

|

MODEL

|

SMD-80D

|

|

SPEED

|

70-80PCS/MIN

|

|

MAX CUP SIZE

|

175(Top diameter) * 95 (Top diameter)*135 MM(Height)

|

|

MATERIAL

|

135-450GRAM

|

|

CONFIGURATION

|

ULTRASONIC&HOT AIR

|

|

OUTPUT

|

380V/220V,60HZ

|

|

AIR COMPRESSOR

|

0.4 M³/Min

|

|

NET WEIGHT

|

3.4 TONS

|

|

MACHINE SIZE

|

2500 ×1800 ×1700 MM

|

|

COUNTER SIZE

|

900 ×900 ×1760 MM

|

Product Advantages:

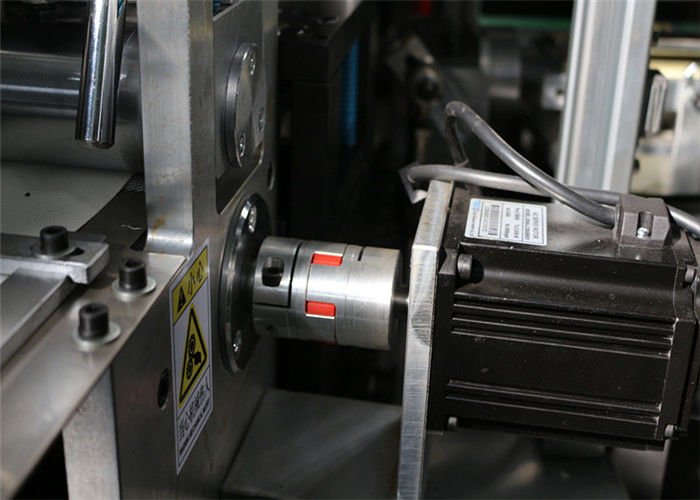

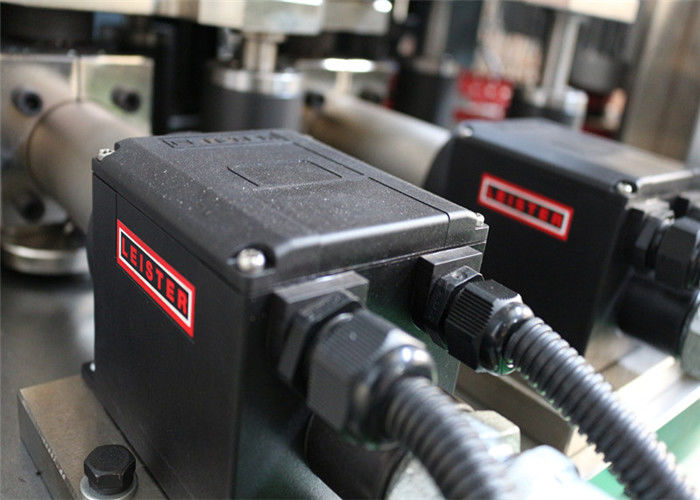

1. 2 sets of original imported hot air system Leister guarantee the stability of heating.

2. Ultrasonic seal the paper cup body,can produce both single and double PE coated paper.

3. Panasonic photoelectricity checking the every part and report.

4. Open cylindrical can divide locating,heigh precision.

5. Automatically Oil lubrication system .

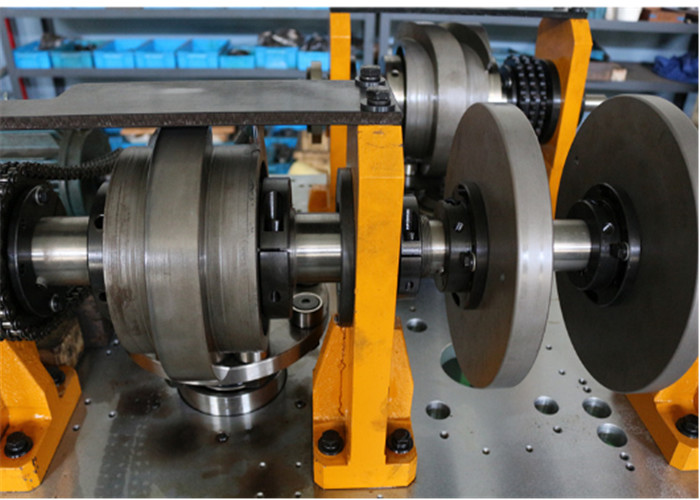

6. Gear work, long life for machinery

7. Inspection system by camera

8. Photoelectricity to track every step

Applications:

donerbox,asianbox,chinesesfood box,foodbox, take away doner kebad box...

About Us:

Haining Chengda Paper Cup Machinery CO.,Ltd is established in year 1998, as Chinese earliest

paper cup machine manufacturer--design,research,manufacture,sell and serve , we have developed,

matured and specialized in machine types as below,

--Middle speed paper bowl machine SMD-80B 70-80cups/min

--Middle speed double wall paper cup machine SMD-80A 80-100cups/min

--High speed paper cup machine SMD-90 100-120cups/min

With decade years of technology accumulation,advanced manufacturing skills and thoughtful after-sale

services, Chengda(Shunda) Paper Cup Machinery CO., Ltd has self-supported import and export right

and goes though CCC and CNAS certificates,also get CE and ISO9001 certified.

Exhibition Show:

FAQ:

1. Is your company a factory or trading company?

Our company is a factory, also have export license.

2. Where is your factory located? How can I visit there?

Our factory is located in haining City, Zhejiang Province, China,

about 1.5 hours by car from Shanghai .All our clients, from home or abroad,

are warmly welcome to visit our company !

3. How does your factory do regarding quality control?

Quality is priority. Shunda people always attach great importance to quality

controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

4. Will you teach how to use the machine?

Yes, engineers available to service machinery overseas or learn in our factory.

5. How about the shipment?

Normally 35-45 days after confirming order, detail delivery date should be decided according to

production season and order quantity.

6. Which payment term do you accept?

T/T, L/C

7. Do you have warranty?

1 year for electronic parts from shipment date

3 years for mechenical parts from shipment date

QC team:

A QC team with more than 10 professional and technical personnel. To ensure 100% products checking.

Material: Strictly control of material using, meet international requested standards.

Semi-finished products inspection: Product inspection before 100% finished.

Production line test: With work team or data engineer who will inspect machines and lines at fixed period.

Finished Product Inspection: Quality and property test before products are packed and loaded.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!