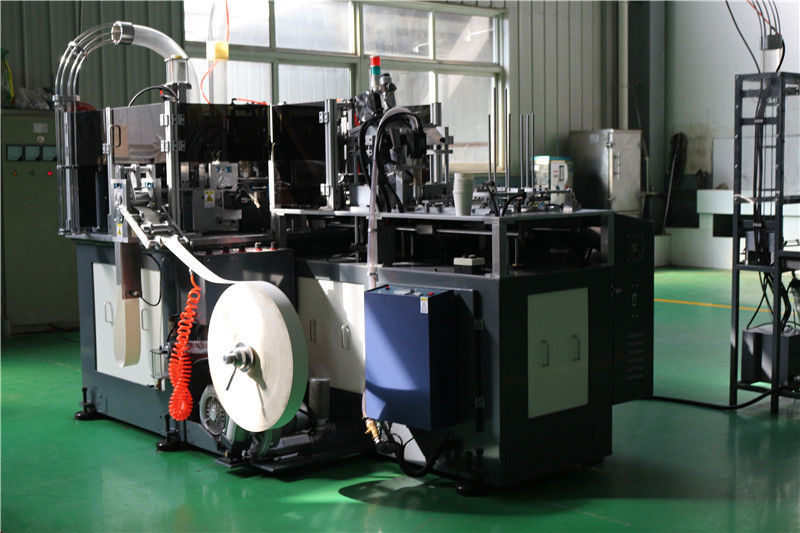

Hot Air System Automatic Paper Cup Machine Three Phase 60HZ 12KW

Advantage:

1.It has 2 sets of original imported hot air system Leister guarantee the stability of heating.

2.Ultrasonic seal the paper cup body,can produce both single and double PE coated paper.

3.Panasonic photoelectricity checking the every part and report.

4.Open cylindrical can divide locating,heigh precision.

5.Automatically Oil lubrication system .

Product Pictures of automatic paper cup machine

Details:

1.Panasonic photoelectric tracking can check every part and report.Imported from Jpan.

2.2sets of Leister original hot air system guaranntee the stability of heating.Imported fom Switzerland.

3.Servo motor control the gap of the bottom-paper within 0.1mm.

4.Gear and open cylindrical promote the stability and speed.

4

Product Description of automatic paper cup forming machine

|

MODEL

|

SMD-90 PAPER CUP MACHINE

|

|

Speed

|

90 PCS/MIN

|

|

Cup size Range

|

<16oz

|

|

Material

|

Single and Double PE coated paper

|

|

Paper request Gram

|

135-450GSM(single and double PE coated paper)

|

|

Heating system

|

Hot air system (from Switzerland)

|

|

Output

|

380V/220V 16 KW,50HZ, Three Phase four wire

|

|

Air compressor

|

0.5 M³/Min

|

|

Net weight

|

4 TONS

|

|

Machinery Size

|

2500 ×1800 ×1700 MM

|

|

Counter Size

|

900 ×900 ×1760 MM

|

paper cups:

More Products for You to Choose

About us

Haining Chengda Machinery Co.,LTd always abides by the business strategy of "high-quality products & reasonable price", the service concept of "showing respect to you & trying my best", and the professional spirit of ’’honesty, innovation, enthusiasm, sureness" to provide customers the best products and services. With a history of over 12 years, ship to more than 100 countries.

Why Choose Us

♦ Advantages

- Quality assurance both for our products and service for after-sales.

- Favorable price.

- Great variety of products.

- Attractive design.

- Environment Friendly Technology

- OEM and ODM service provided.

♦ Our QC team

A QC team with more than 10 professional and technical personnel. To ensure 100% products checking.

Material: Strictly control of material using, meet international requested standards.

Semi-finished products inspection: Product inspection before 100% finished.

Production line test: With work team or data engineer who will inspect machines and lines at fixed period.

Finished Product Inspection: Quality and property test before products are packed and loaded.

Certificate

Trade Show

More than 1000 exhibitors and over 20 thousand visitors from the world flooded into Algiers,Algeria International fair on June .The trade fair is a "carnival" of this industry which is held once every year.

Before the Algeria fair 2011 was open, Our ZBJ-9A is very famous in Algeria.

Our Customers

Market & Shipment

FAQ

1. Q: Is your company a factory or trading company?

A: Our company is a factory.

2. Q:Where is your factory located? How can I visit there?

A:Our factory is located in haining City, Zhejiang Province, China, about 1.5 hours by car from Shanghai .All our clients, from home or abroad, are warmly welcome to visit our company !

3. Q:How does your factory do regarding quality control?

A:Quality is priority. Shunda people always attach great importance to quality controlling from the very beginning to the very end: 1).All raw material we used are environmental-friendly; 2).Skilful workers care every details in handling the producing and packing processes; 3).Quality Control Department specially responsible for quality checking in each process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!