135-450 GSM Paper Made Disposable Paper Plate And Cup Making Machine

Description

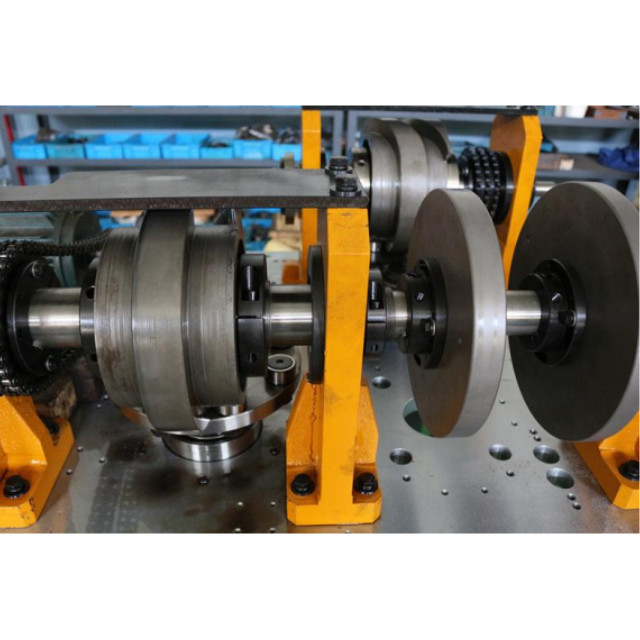

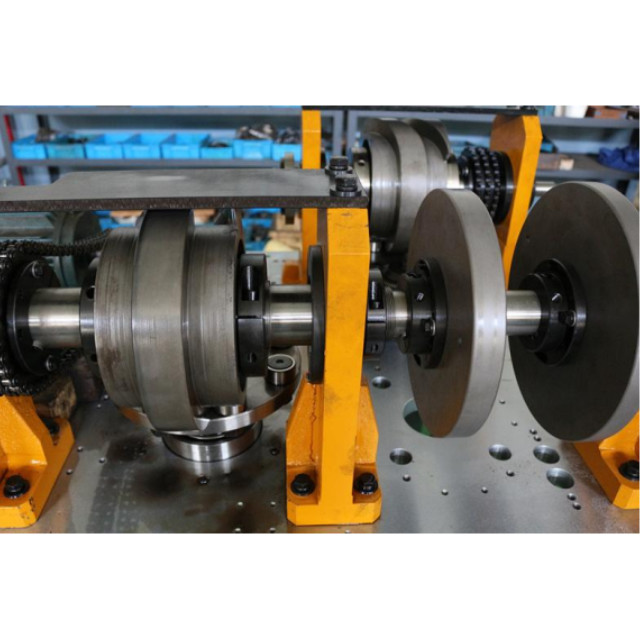

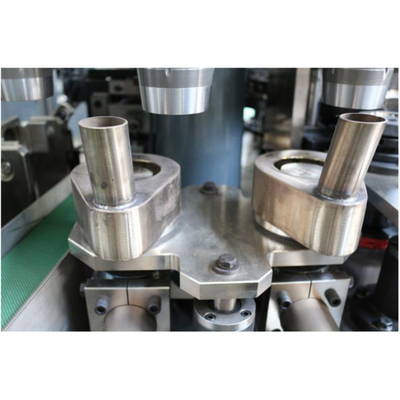

SMD-90 paper cup making machine is an improved and upgraded machine of the low speed types. In order to realize optimal functions and performance, it utilizes open cam design, interrupted division, gear drive and longigudinal axis structure.

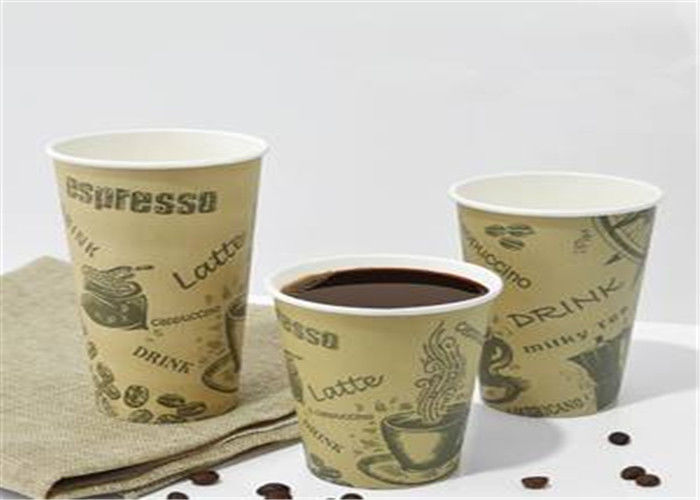

It could produce 3-46 oz cold and hot drink paper cup, such as coffee cup ,tea cup , water cups etc .especially it is popular for making small coffee cup 3oz for Algeria market.

Main Technicial Data

| Model |

SMD-90 |

|

|

|

| Capacity |

pcs/min |

100-120 |

90-110 |

80-100 |

| Size Range |

mm(max) |

Top diameter:90

Bottom Diameter:80

Height:140 |

Top diameter:110

Bottom Diameter:80

Height:170 |

Top diameter:125

Bottom Diameter:100

Height:170 |

| Suitable Paper Thickness |

gsm |

135-450 |

|

|

| Sealing Method |

|

Ultrasonic and hot air system |

|

|

| Running Power |

KW |

10 |

11 |

12 |

| Air compressor |

|

0.4m²/Min. 0.5MPa |

0.5m²/Min. 0.5MPa |

0.6m²/Min. 0.5MPa |

| Net weight |

Kgs |

3400 |

3500 |

3600 |

| Machine dimension |

mm |

2500*1800*1700 |

2600*1800*1800 |

2700*1800*1800 |

| Collector Dimension |

mm |

900*900*1760 |

1000*900*1860 |

1100*900*1860 |

Product advantage :

Can make small sizes cups

Machine size is small,can operate more easy

a.Advanced double barrel cam indexing

b.PLC colsed-loop control system

c.Automatic oil lubrication system

d.Cup inspection and intelligent control

e. Servo control for bottom feeding

f. Flameless hot air sealing

Machine details

Cup Size

Our QC team

A QC team with more than 10 professional and technical personnel. To ensure 100% products checking.

Material: Strictly control of material using, meet international requested standards.

Semi-finished products inspection: Product inspection before 100% finished.

Production line test: With work team or data engineer who will inspect machines and lines at fixed period.

Finished Product Inspection: Quality and property test before products are packed and loaded.

Whole Process

Our Address

FAQ

1. Q: Is your company a factory or trading company?

A: Our company is a factory.

2. Q: Do you have Guiding Box or CD video for clients?

A: Yes,we have,we will send guiding box with CD together to clients.

3. Q: what about your payment?

A: We accept T/T,L/C payment.

Applications:

Shunda SMD-90 Ice Cream Paper Cup Making Machine

Brand Name: Shunda

Model Number: SMD-90

Place of Origin: Zhejiang China

Certification: CE

Packaging Details: Two sets per 20ft container

Delivery Time: 20-25 working days

Payment Terms: LC, TT

Supply Ability: 20 sets a month

Capacity: 130 Cups/min

Warranty: 2 Years

Application: Paper Cup Production

Collector Dimension: 900*900*1760mm

Power Supply: 220V/380V

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!