High Speed Automatic Intelligent Paper Cup Bowl Lid Cover Making Forming Machine

Technical Parameter

| Model |

PLM-60 small size |

PLM-60 big size |

| Speed |

50-60 pcs/min |

50-58 pcs/min |

| Lid size |

Diameter: 60-120mm |

Diameter: 80-160mm |

| |

Height:12-25mm |

Height:12-25mm |

| Raw material |

300-450gsm PE/PLA coated paper |

300-450gsm PE/PLA coated paper |

| Configuration |

Ultrasonic |

Ultrasonic |

| Output |

5.5KW, 380/220V,60/50HZ |

6.0KW, 380/220V,60/50HZ |

| Air compressor |

1.2M³/Min 0.5MPA |

1.3M³/Min 0.5MPA |

| Net weight |

2.0 Tons |

2.2 Tons |

| Dimension of machine |

1700×1600 ×1500 mm |

1800×1700 ×1500 mm |

| Dimension of collector |

1500x500x1200 mm |

1500x500x1200 mm |

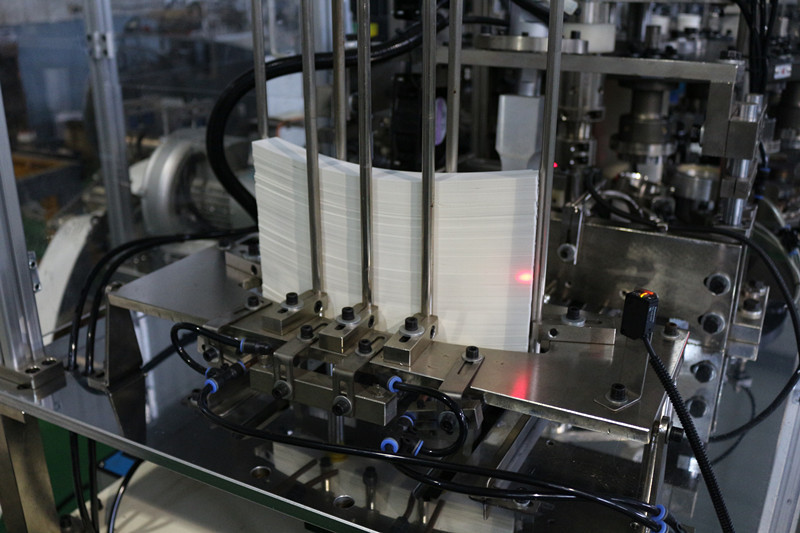

PLM-60 is designed to make paper lid for cup, bowl and bucket.

Main Structions:

1. Hot air system guarantee the stability of heating.

2. Ultrasonic seal the paper lid body, suitable for both single and double PE coated paper.

3. Open cylindrical cam divide locating, high precision.

5. Automatically Oil lubrication system inside, oil can be recycled used.

6. Gear drive, long life for machinery.

7. Photoelectricity to track every step.

Detail instruction:

Lid Body Sealing

Name: Ultrasonic

Brand: EVERGREEN/Rongzhen

Original: Taiwan/CN

Features:

Ultrasonic sealing for lid body, both okay for single or double pe coated paper.

Lid Bottom Pre-heating

Name: Heating Device

Original: CN

Features:

pre-heating make bottom sealing firmly

Gear Drive System

Features:

1. Make running more stable

2. High Precision

Oil Lubrication System

Features:

1. automatic spray engine oil to gears, chains

2. less human maintaince

3. oil can be recyced used

4. clean and change oil half a year

PLC control Panel

Simple and efficient control panel, mady by MITSUBISHI. make work more intelligent.

Photoelectric

Features:

Panasonic Photoelectricity sensor to track every step.

Auto alarm when paper fan go short

Auto stop when multi paper fans devlier

Auto paper fan track and deliver

Problems show in PLC display screen.

Finished Products Show:

About us:

Haining Chengda Machinery Co.,LTd always abides by the business strategy of "high-quality

products & reasonable price", the service concept of "showing respect to you & trying my best",

and the professional spirit of ’’honesty, innovation, enthusiasm, sureness" to provide customers

the best products and services. With a history of over 20 years, ship to more than 100 countries.

Trade Show

FAQ

1. Q: Is your company a factory or trading company?

A: Our company is a factory.

2. Q:Where is your factory located? How can I visit there?

A:Our factory is located in haining City, Zhejiang Province, China, about 1.5 hours by car from Shanghai. All our clients, from home or abroad, are warmly welcome to visit our company !

3. Q: How does your factory do regarding quality control?

A: Quality is priority. Shunda people always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

4.What information should i let you know if i want to get a quotation?

--Quantity

--The detailed size (top diameter,bottom diameter,and height)

--The paper thickness

5.what's your advantages?

--20 years experience:We have been in making paper cup machine for 20 years.

--Customers all over the world

--Fast reply:Our team will reply you soon.

--After-sale service:We have a after sale department , service for your problems

and dealing with spare parts.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!